Efficient operations, minimum downtime.

we have in-house engineering capability to develop weld mapping for the piping systems to facilitate the fabrication and installation processes, where our customers (i.e. main contractors, subcontractors or industrial end-users) will typically provide us with

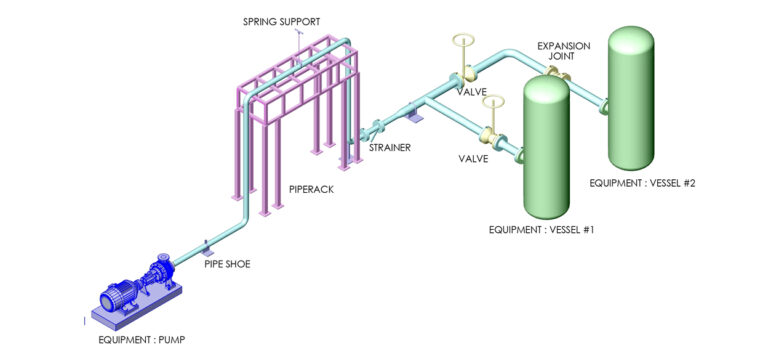

the engineering design drawing. The weld mapping that we develop shows details such as cut lengths, weld details, valve and instruments locations, spool identifications, support types and spacing, where necessary

Precision Weld Mapping

Our in-house team develops accurate weld mapping to ensure every joint, spool, and connection meets project design requirements and quality standards.

01.

Technical Expertise

We combine practical field experience with engineering knowledge to support smooth fabrication and installation processes across all project stages.

02.

Seamless Coordination

We work closely with main contractors and clients to ensure drawings, specifications, and material details align for efficient execution.

03.

Quality & Reliability

Our engineering ensures every piping system is built to last — delivering safe, reliable, and high-performance results for industrial applications.

04.

explore

Our services

Procurement & Sourcing

Fabrication